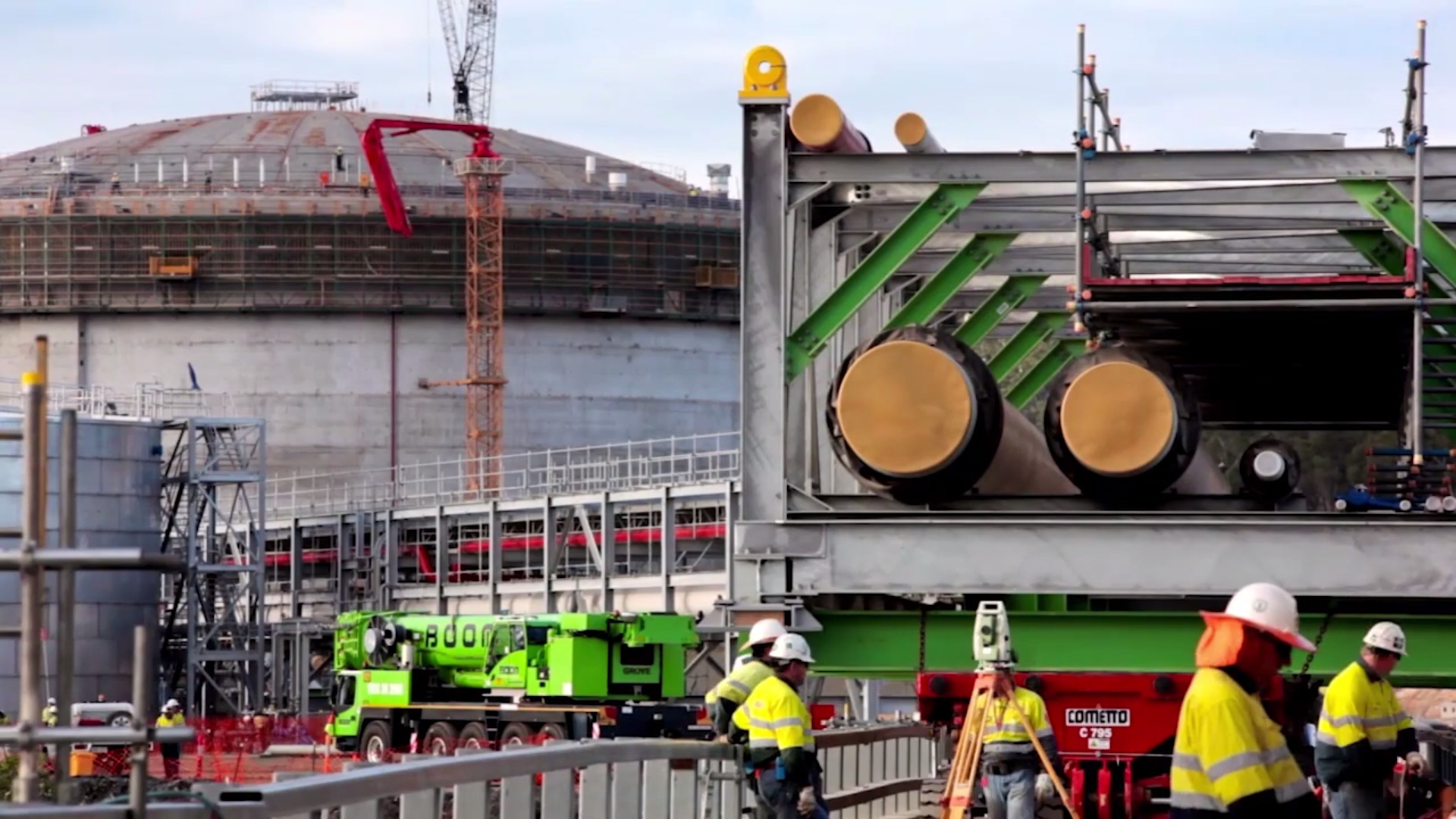

Cameron LNG presented a unique design challenge. The pipe route was defined by existing structure, and so our experienced design team had to work very closely with our client to ensure no civil changes were required.

Our innovative design provided an opportunity for fittings, branch connections, and field welds – traditionally a point for major heat inleak – to be completely vacuum insulated, and meet FERC’s requirement for total secondary containment. As normal, we performed all stress & flexibility analysis at Cryeng’s head office in Sydney.

STATS:

- Dec ’15 – Nov ’16

- Pipeline Length: 1.3km

- Spools: 71

- NPS: 24″, 30″ , 36″

- 50+ elbows, 10 tees & reducers

- 10+ vacuum insulated branch connections