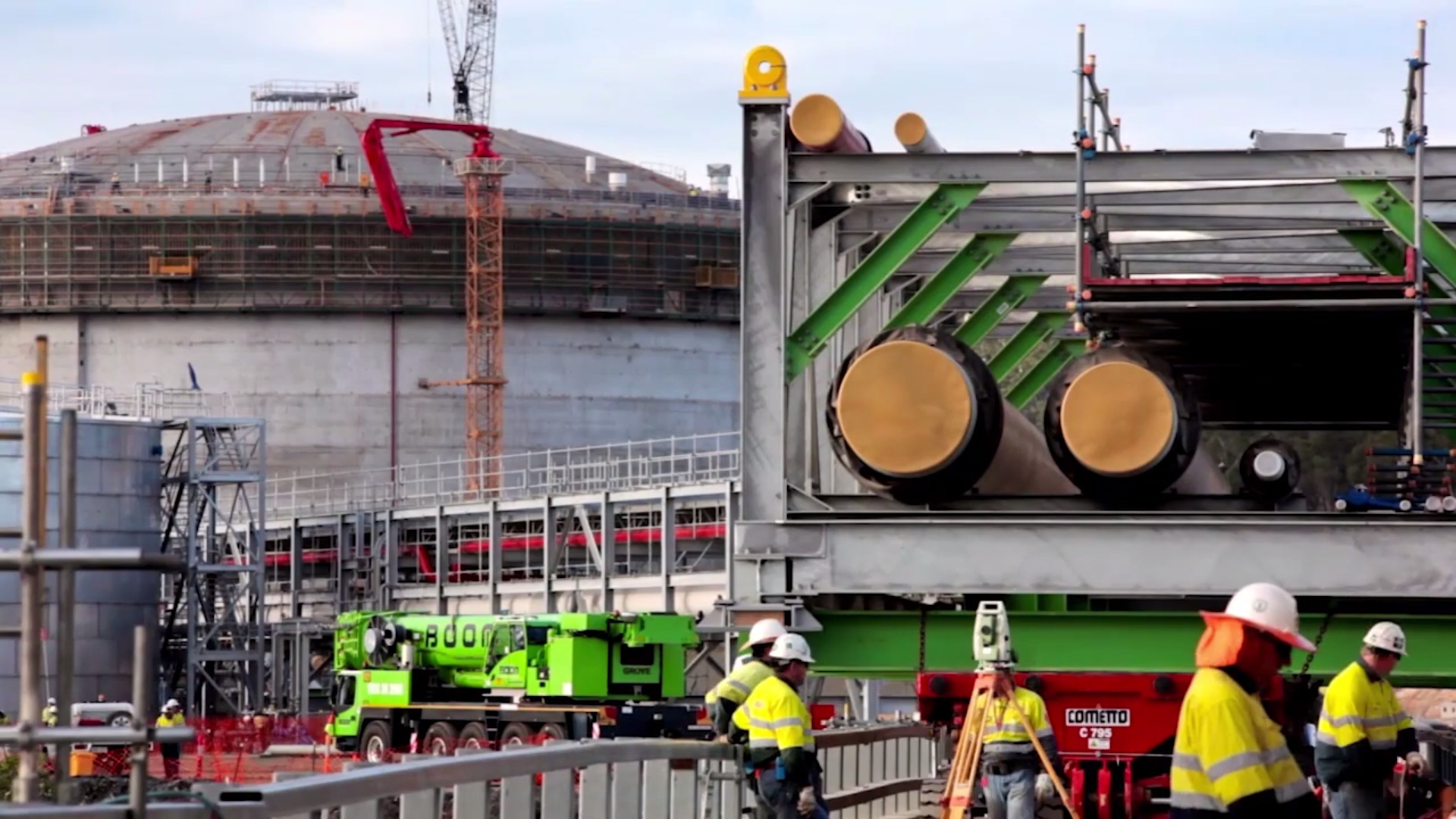

Freeport LNG selected Cryeng Group’s vacuum insulated pipe due to our superior thermal insulation, coupled with complete secondary containment, now legislated by the US Government (FERC).

Our team performed the complete flexibility & stress analysis of the pipeline. We were able to nearly eliminate all expansion loops, while accommodating complex design features such as underground road crossings and congested valve platform areas. As the client’s plant design matured, our scope changed significantly. But because we do all the fabrication inhouse, we were able to easily accommodate changes.

Partway through the Freeport LNG project, Cryeng Group was awarded the Freeport Train 3 Pipeline Project: a reflection of our excellent engineering design and support.

STATS:

- Jan ’16 – Mar ’17

- Pipeline Length: 6km

- Spools: 274

- NPS: 6″, 8″, 18″, 20″, 22″,24″ 26″, 30″

- 250+ vacuum insulated elbows, tees, reducers

- 25+ vacuum insulated branch connections